Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

Fortify and PTC worked together to prove out if water cooling channels designed into the 3D printed mold tool could help reduce cycle time.

JEC Europe 2013 new product showcase

TCT Europe 30.4 by TCT Magazine - Issuu

Current Status in the Utilization of Biobased Polymers for 3D Printing Process: A Systematic Review of the Materials, Processes, and Challenges

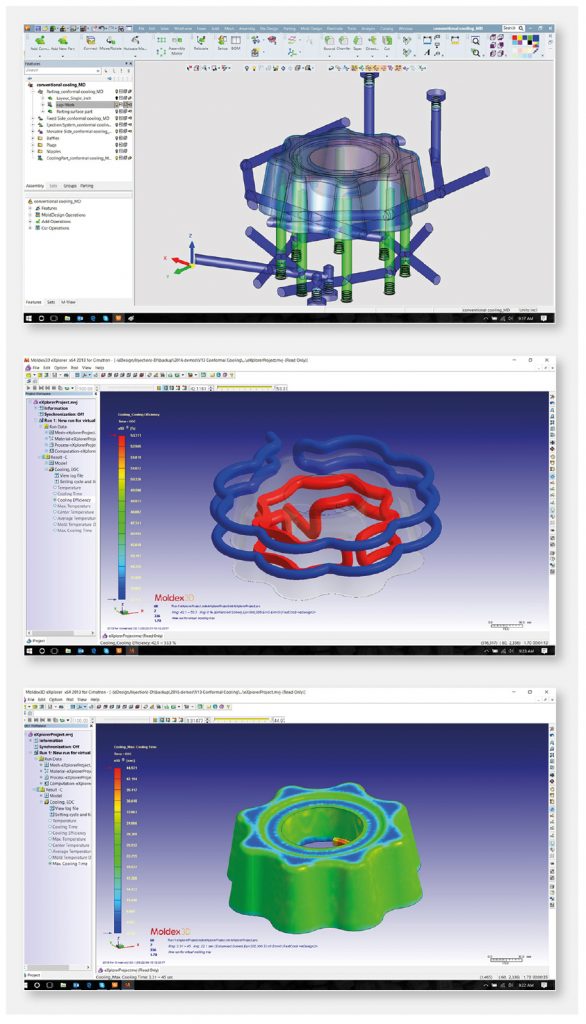

Moldex3D Plastic Injection Molding Simulation Software

Conformal Cooling: Higher-Quality Parts, Faster Injection Molding Cycle Times - SyBridge Technologies

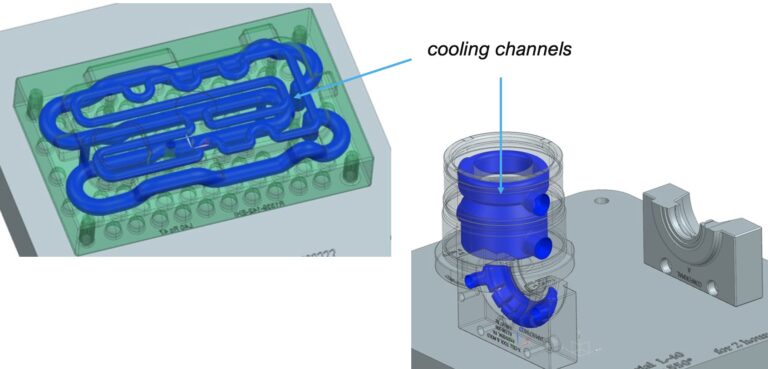

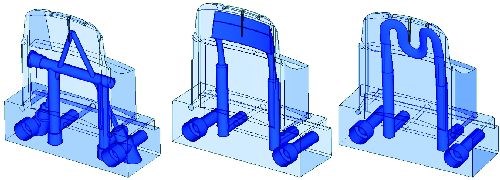

Conformal cooling: How Additive Manufacturing benefits injection moulding

Strategies To Modify the Surface and Bulk Properties of 3D-Printed Solid Scaffolds for Tissue Engineering Applications

Benjamin MacDonald on LinkedIn: #molddesign #moldmaking #additivemanufacturing #molds

Reduce 33% Cycle Time through CAE Evaluation Method of Conformal Cooling System, Blog, Moldex3D

Conformal Cooling: A Tool in the Toolbox to Build a Better Mold

WEBINAR: RAISING THE BAR FOR 3D PRINTED TOOL PERFORMANCE

Fortify expands fiber-reinforced photopolymer 3D printing line for end-use part applications

Conformal Cooling Transforms Injection Molding Processes and Part Quality - Linear AMS

Conformal cooling: How Additive Manufacturing benefits injection moulding